Maximizing Equipment Longevity: Buying Premium Undercarriage Parts Solutions

Maximizing Equipment Longevity: Buying Premium Undercarriage Parts Solutions

Blog Article

Maximize Performance With Long Lasting Undercarriage Components

In the realm of heavy machinery and tools, the duty of undercarriage parts is extremely important in guaranteeing ideal efficiency and longevity. The effectiveness and efficiency of these components can significantly influence the general procedure of machinery, making the choice of resilient undercarriage parts a critical choice for managers and drivers alike.

Benefits of Making Use Of Resilient Undercarriage Components

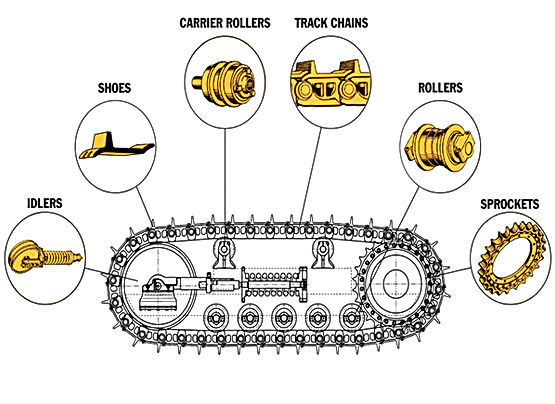

Using long lasting undercarriage components not only enhances the long life of heavy equipment but likewise minimizes maintenance expenses dramatically. By investing in high-quality undercarriage components, such as tracks, rollers, gears, and idlers, tools operators can experience enhanced uptime and boosted total performance.

Additionally, the long life of hefty machinery is straight linked to the high quality of its undercarriage components. Resilient parts can stand up to the rigors of requiring applications, guaranteeing that the devices remains operational for extended periods. Because of this, operators can stay clear of expensive downtime and upkeep costs, inevitably taking full advantage of the return on financial investment for their machinery.

Elements Affecting Undercarriage Toughness

The resilience of undercarriage components in hefty equipment is affected by numerous essential elements that directly impact performance and longevity. One of the vital aspects influencing undercarriage sturdiness is the quality of products used in production. Top quality materials, such as hardened steel, are important for enduring the severe conditions and hefty lots that undercarriage parts undergo. Appropriate maintenance methods also play a crucial duty in establishing the lifespan of undercarriage elements. Normal examinations, lubrication, and prompt replacement of damaged parts can significantly expand the toughness of the undercarriage.

Furthermore, ecological factors can have a substantial effect on the longevity of undercarriage components. Exposure to abrasive products, extreme temperature levels, and extreme working conditions can increase deterioration on undercarriage parts. Picking undercarriage components that are particularly designed to endure these environmental challenges is essential for ensuring durability.

Additionally, the design and engineering of undercarriage parts have a direct influence on their resilience. Components that are created to distribute tons uniformly, minimize rubbing, and lessen anxiety concentrations are more probable to have a much longer lifespan - undercarriage parts. By considering these critical elements, devices operators can take full advantage of the durability and performance of their undercarriage components

Maintenance Tips for Lengthening Undercarriage Life

Applying regular upkeep routines is vital for extending the life-span of undercarriage parts in heavy machinery. In addition, ensure that the undercarriage is appropriately lubed according to supplier standards to reduce friction and prevent premature wear.

Another vital maintenance idea is to keep the undercarriage clean from dirt, rocks, and particles. Accumulation in the undercarriage can accelerate wear and rust, resulting in pricey repair services. Cleaning the undercarriage after operation in severe problems is advised to stop these concerns.

Last but not least, monitoring and recording upkeep activities can aid in creating a positive upkeep timetable. Maintaining comprehensive records of repair services, examinations, and substitutes can supply valuable understandings into the undercarriage's problem and performance with time, aiding in predicting and stopping possible failures. By adhering to these upkeep pointers vigilantly, operators can dramatically boost the sturdiness and efficiency of undercarriage parts in hefty equipment.

Picking the Right Undercarriage Parts

Picking ideal undercarriage parts is the original source crucial for taking full advantage of the efficiency and long life of heavy machinery. There are numerous elements to think about when it comes to selecting the appropriate undercarriage parts. One essential variable is understanding the details needs of the machine and the atmosphere in which it will operate. Various applications might call for different kinds of undercarriage parts, such as tracks, sprockets, rollers, and idlers. It is vital to choose parts that are created to withstand the certain problems the maker will encounter, whether it be rough terrain, rough products, or extreme temperatures.

Additionally, taking into consideration the quality and track record of the producer is important. Selecting reliable brands understood for generating high-performance and sturdy undercarriage components can substantially affect the overall performance and long life of the equipment. Ensuring that the components are compatible with the equipment version and properly installed is essential for ideal efficiency. By thoroughly picking the best undercarriage elements, equipment proprietors can enhance performance, lower downtime, and extend the life expectancy of their heavy machinery.

Study: Enhanced Efficiency With Resilient Components

Including resilient undercarriage components has actually demonstrated significant enhancements in machinery performance. One instance research study included a building business that upgraded its excavator's undercarriage parts to a lot more long lasting options.

In another instance, a mining operation changed the undercarriage components of its bulldozer with premium, durable choices. This switch brought about an exceptional renovation in the bulldozer's maneuverability and total efficiency. The equipment might navigate challenging surfaces a lot more efficiently, causing boosted operational efficiency and lowered gas usage.

Furthermore, a logging company purchased sturdy undercarriage components for its forestry tools. The upgraded parts showed long term life expectancy and enhanced resistance to abrasion from harsh surface. The company experienced reduced upkeep costs and enhanced equipment uptime, eventually increasing its lower line. These study emphasize the substantial advantages of utilizing durable undercarriage parts in optimizing machinery efficiency and longevity.

Conclusion

In verdict, utilizing durable undercarriage components can significantly enhance performance and longevity of hefty machinery. Situation researches have revealed that investing in sturdy undercarriage components can lead to enhanced general efficiency and productivity in numerous markets.

The effectiveness and effectiveness of these elements can this hyperlink significantly influence the general operation of machinery, making the choice of sturdy undercarriage parts a crucial decision for operators and managers alike.Including durable undercarriage components has demonstrated substantial enhancements in equipment efficiency. These situation researches underscore the substantial benefits of utilizing long lasting browse around this web-site undercarriage parts in optimizing machinery efficiency and longevity.

In conclusion, using durable undercarriage components can substantially boost efficiency and durability of heavy machinery (undercarriage parts). Instance research studies have shown that spending in durable undercarriage components can lead to improved general performance and efficiency in different markets

Report this page